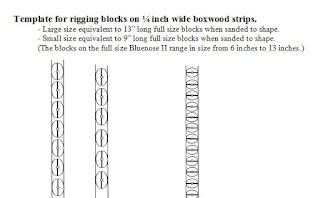

Having generated templates for the two sizes, these were then pasted on 1/4" X 1/8" strips of boxwood. For the smaller blocks, the long dimension was positioned across the strip; for the larger block, the long dimension was positioned lengthwise. The picture below shows some of the smaller blocks cut from the strip, ready for shaping.

Small block template applied to boxwood strip, ready for shaping.

Once separated, I used the Dremel tool with a mini-sanding drum to rough out the shape to the template.

Deremel tool, table-mounted with sanding drum.

Shaped boxwood block, ready for detailing.

At this point, another decision was required. On the Bluenose II, the modern-style blocks do not have external stropping. This is in contrast to older blocks, which had an external band (or strap) to both hold the block together as well as attach the eyes (used to secure other hardware such as hooks, shackles,and thimbles to the block). Since I wasn't prepared to make a "built-up" block with internal hardware, the external stropping approach seemed the obvious way to go.

Besides, I think the stropping adds to the visual effect - without it, the blocks look a little bland.

(After build note: Although at this point in the build I was still intending to configure the model as the Bluenose II, in the end, I decided to fit it out as the original Bluenose and so the stropped blocks look just right.)

(After build note: Although at this point in the build I was still intending to configure the model as the Bluenose II, in the end, I decided to fit it out as the original Bluenose and so the stropped blocks look just right.)

After some experimentation, I settled on the following method to produce the blocks. First, drill a hole at one end of the block to represent the sheave, through which the rigging will run.

Drilling the sheave "hole".

Detailing the sheave.

Finally, cut a grove on each side of the block to hold the stropping.

Cutting grove for stropping.

With these details done for all blocks, I started on the stropping. Twenty-seven gauge wire was used; anything smaller was unlikely to retain its shape when formed into eyes and subjected to the strains of rigging. Eyes were formed using a suitably size rod; in this case 1/16". A hole drilled into the building board held the rod and allowed me to form the eye. The following series of pictures are self-explanatory.

Rod and wire, ready to form an eye.

Two loops to form the eye.

Wire stropping applied to the block.

Securing the stropping.

With the stropping wire twisted secure and the excess cut off, the block is essentially finished. In those instances where an eye is needed at both ends, a loop of wire will be inserted at the other end.

Finished block. Tried an ink spot to simulate sheave axle. (Not applied to final versions.)

Complete blocks dipped in urethane hanging to dry.

For double and triple sheave blocks, wood strips were glued together prior to shaping.

|

| Completed one, two and three sheave large blocks and single and three sheave small blocks. |

|

| Single sheave small block. |

|

| Double sheave small blocks. |

Next post: the sails.